Concentrol is a chemical solutions company that works for multiple industrial sectors through its four divisions: Performance Materials , Food Processing Aids , Additives and Adhesives .

Within the Performance Materials division , the solutions with the greatest outlet on the current market are release agents , a chemical specialty for the final application of the product that has great added value for customers.

These products are used to create molded polyurethane parts, elements present in a wide variety of sectors and applications. They are recurrent in the manufacture of products such as mattresses, furniture, panels and blocks for construction, footwear, polyurethane systems, electrical or automotive applications, among others.

There are a series of critical factors that must be taken into account when choosing the use of a specific mold release agent. These are:

- Quantity of VOCs

The use of mold release agents involves the emission of different degrees of Volatile Organic Compounds (VOCs) and aerosols, one of the most present pollutants in the atmosphere. One of the most agile options to achieve a reduction in VOC emissions is based on changing the release agent with low solids content to a concentrated one ready to use.

- Inflammability

When using mold release agents, it is always necessary to consider the possibility of forming an Explosive Atmosphere (ATEX). This fact conditions the regulation of the facilities in which work is carried out, the danger according to the flash point (Class) and other aspects related to the transportation and storage of the products.

- Toxicity

The products involved in the formulation of release agents have a certain degree of toxicity. This occurs, especially, with those that refer to tin compounds, and this has a direct impact on the work environment.

- Final impact on the environment

Working with mold release agents can lead to tin compounds and other toxic materials, potentially dangerous for the environment, being released into the environment.

Mold release agents can be solvent-based, water-based or hybrid. Some time ago, all producers in the chemical sector used solvent-based mold release agents, but over time the sustainability of these solutions began to be questioned.

Water-based mold release agents, the most sustainable solution

For the manufacture of polyurethane (PU) foams, experts recommend leaving aside the use of solvent-based release agents and opting for water-based ones, which are more sustainable. However, there are certain aspects of water-based release agents that pose some limitations, making some manufacturers still reluctant to take the plunge and use them in their production plants.

The release agent sector is in continuous growth and development, which means that better solutions are increasingly offered that reduce the limitations of these materials. Thus, these solutions are increasingly getting closer to the results obtained with traditional solvent release agents.

Following the industry trend, Concentrol’s R&D team of researchers is also working exhaustively to improve its mold release solutions. That is why they have created a comparative study of water-based products designed for the release of cold-curing polyurethane foam, in order to give the same behavior and finish as solvent-based products.

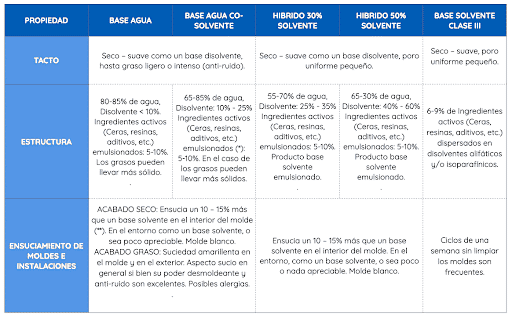

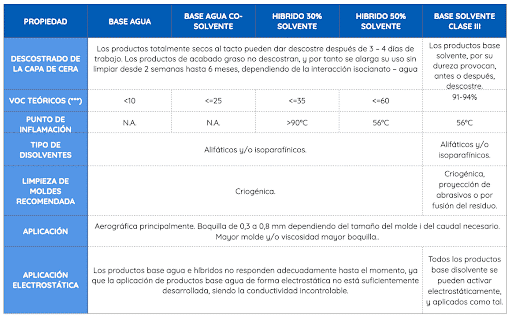

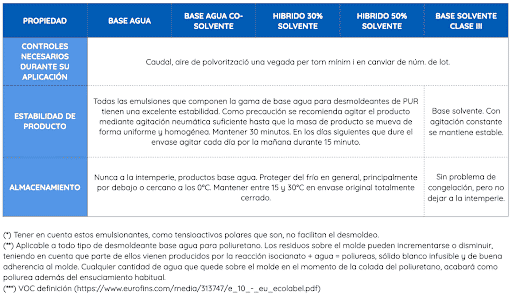

The summary of the conclusions of this study can be seen in the following summary table:

STRUCTURE AND PROPERTIES OF THE PRODUCT

Given the results of the comparative study, the team has been able to have an overview of the strengths and also the aspects to improve its range of release agents. However, the main characteristic to take into account after the comparison is related to the issue of sustainability. In order to continue caring for the planet and the health of workers, Concentrol will continue to opt for water-based mold release agents, which are the most sustainable solution.