The chemical solutions company Concentrol is structured into four large divisions: Performance Materials , Food Processing Aids , Additives and Adhesives .

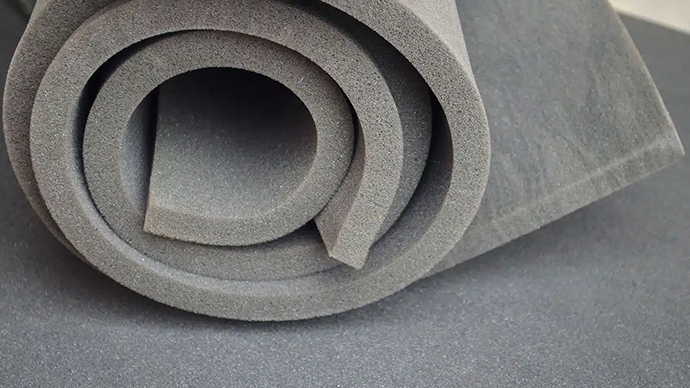

The professionals in the Performance Materials division work mainly with two materials, polyurethane foam , which gives rise to several products, and wood, which is one of the company’s future bets.

Release agents for polyurethane foams are a chemical specialty designed for the final application of the product. This product has a high added value for the customer, and the choice of one release agent or another may have to do with many factors such as environmental impact, the cost of its use or efficiency.

Type of release agents

- Solvent based

Originally, solvent-based release agents were almost always used , solutions that were not very sustainable and, in addition, in some cases compromised the health of workers, since they were exposed to solvents. This exposure is measured through the TLV/DNEL values, related to the solvents formulated in the release agents.

- Water based

Progressively, original equipment manufacturers (OEMs) have pressured the industry to eliminate VOCs and thus make the switch to water-based mold release agents . This change has come in parallel to formulating release agents that would achieve pieces with a drier finish , which, for example, would allow heating sheets and auxiliary textiles to be attached to their surface without having to sacrifice release capacity.

Along these lines, one of the most difficult challenges in recent years has been to reduce the greasy finish that water-based release agents can give to parts.

- Co-solvents

Between solvent and water-based mold release agents are co-solvents and hybrids.

Co-solvent mold release agents contain 75 to 85% water base and 5 to 15% solvent . It is also worth noting that these have a shorter drying time and produce better emulsions of waxes and active ingredients than 100% water-based systems.

- Hybrids

Hybrid release agents are based on the vehicle of the active ingredients being 50% water and 50% solvent . In terms of their functionality and finish of the pieces, they are like solvent-based mold release agents, but their formulation contains half the VOC’s.

There are also a couple more options, halfway between solvent-based and water-based release agents, which are concentrated release agents and electrostatic release agents.

- More concentrated mold release agents

There are those who choose to apply less amount of mold release agent, but make it more concentrated . In this way, users are allowed to reduce TLVs, VOCs and, ultimately, improve the health of workers who have direct contact with these substances.

- Electrostatic release agents

This is the most technically sophisticated approach. The release application gun is connected to an electrical pole that is negatively charged, while the working mold is connected to a positive pole. By applying a high voltage current, an electrostatic field is generated between the electrode at the gun tip and the mold. When the applicator presses the trigger to start the flow of the release agent, the aerosol particles are negatively charged. Taking into account that opposite charges attract, the mold attracts the release agent, efficiently covering its entire surface. This helps avoid unnecessary losses and reduce consumption and environmental impact .

Today electrostatic solutions do not have strong odors or additional toxicity, and can be used with class I, II or III solvents.

The use of electrostatic mold release agents prevents overspray of mold supports, floors and the surrounding environment. This, in practice, means that there is a large reduction in consumption , between 30 and 50% compared to conventional systems. In addition, with this system there is a significant reduction in the VOC’s emitted, also between 30 and 50%, which helps to improve the work environment.

Electrostatic demolding systems are usually applied through robotic systems , which requires an investment in specific equipment. Also keep in mind that spray guns will be larger and heavier than those typically used.

Tin-free mold release agents, a relative success

Over time, the polyurethane industry has evolved its solutions to obtain components that are increasingly more respectful of the planet.

Tin is an organometallic compound that has been neglected as a result of its strong impact on the environment. Although it was widely used for a long period of time, it is no longer used much because it is a very difficult component to degrade in the natural environment .

Mold release agent suppliers have been working to replace organotin compounds with other organometallic compounds . The truth is that the new solutions have had moderate success, since the new materials have some limitations.

Important tin-based compounds are tin octoate, tin dibutyl dilaurate (DBTDL), and tin mercaptide. Certain salts of lead, mercury and antimony have also been used. The replacement of DBTDL as a catalyst with other non-organotin substances is possible thanks to cutting-edge knowledge, collaboration and testing with customers to produce tailored products.

Reducing flammability, a challenge under study

To reduce the risk of flammability of release agents, the best option is to switch from a solvent-based release agent to a water-based release agent, although there are alternatives.

One option is to upgrade the release system to use a less volatile solvent .

The polyurethane industry in the European Union treats solvents according to European Directive 67/548/EEC, which classifies them into three groups:

- Class I: Easily flammable. Substances with a flash point below 21ºC.

- Class II: Flammable. Substances with a flash point between 21 °C and 55 °C.

- Class III: Fuels. Substances with a flash point greater than 55 °C.

For example, if a modeler was using a Class I release agent, which may contain heptane and has a flash point less than or equal to 0°C, the logical step is to change to a Class II release agent with a flash point of 28°. c. This may contain C9-C10 gasoline.

Switching from a Class II to a Class III system, based on isoparaffin and with a flash point above 55°C, would again significantly reduce volatility. Switching to higher flash point solvents is a good way to quickly reduce VOC’s and TLVs, but with increasing flash point temperature, drying time will be longer. As it will take more time to dry the molds before pouring the polyurethane, it must be taken into account that the work chain on the production line will become more critical.

VOC’s and their environmental impact

VOCs , Volatile Organic Compounds, are one of the polluting agents that have the greatest impact on the atmosphere . These components are key in the formation of ozone in the troposphere and at ground level because they form nitrogen oxides that contribute to global warming.

The chemical reactions involved in the formation of tropospheric ozone consist of a series of cycles in which carbon monoxide and VOCs are oxidized to water vapor and carbon dioxide, both of which contribute to climate change.

The European Union and the WHO, the World Health Organization, define a VOC’s as any organic compound that has an initial boiling point less than or equal to 250 °C measured at a normal atmospheric pressure of 101.3 kPa.

Volatile organic compounds are organic chemical compounds containing carbon atoms with a high vapor pressure at room temperature. This vapor pressure is related to the boiling point, and the lower the boiling point, the faster the molecules evaporate into the air.

TLV and DNEL, indicators to take into account for the health of workers

TLVs , Threshold Limit Values, are the concentrations of substances suspended in the air . These are important values to take into account, especially for those people who work with the mold release agents that wrinkle the molds.

TLVs mark the conditions under which it is believed that almost all workers can be repeatedly exposed on a day-to-day basis without showing adverse health effects .

The TWA , the Weighted Average Concentration, is the concentration of substances to which workers can be repeatedly exposed without adverse health effects, and is calculated for an 8-hour work day and a 40-hour week. These data are useful in defining the size and strength of the plant’s extraction capacity to ensure that the TLV for each solvent is not violated.

The DNEL , the Derived No Effect Level, is the level of exposure to a substance above which humans should not be exposed .

Under EU legislation, chemical manufacturers and importers must calculate the DNELs of any chemicals used in quantities of 10 tonnes per year or more, and incorporate this into their “Chemical Safety Assessments”.

DNELs measure the substance’s potential to cause adverse health effects . This potential will vary depending on the pattern of exposure to the substance, and to calculate it the following is taken into account:

- The population likely to be exposed to the chemical, that is, workers, consumers or humans exposed through the environment.

- The frequency and duration of exposure.

- The route of exposure, which can be dermal, inhalation or oral.

To give a practical example, a C9-C10 dearomatized hydrocarbon, which is a standard aliphatic solvent commonly used as a carrier in mold release agents, contains the following: DNEL (skin contact) of 208 mg/kg body weight / day and DNEL (inhalation) of 871 mg/m³.

If a Class III C11-C12 hydrocarbon is used, the DNEL disappears.