Building Waterproofing

Waterproofing stands as a critical aspect in constructing any structure. It significantly prolongs the sustainable lifespan of a building, enhancing its value while safeguarding against structural damage. This practice minimizes maintenance expenses, enhances indoor air quality, and prevents costly repairs. Additionally, it reduces heating and cooling expenses, ultimately fostering a healthier and more comfortable living environment.

What Is Water Proofing?

Waterproofing involves treating surfaces or structures to make them resistant to water, thus protecting them from potential damage and ensuring they remain unaffected or resistant to water ingress under specific conditions. The terms “water-resistant” and “waterproof” typically denote the ability to resist water penetration in its liquid state, possibly under pressure, while “damp proof” refers to resistance against humidity or dampness.

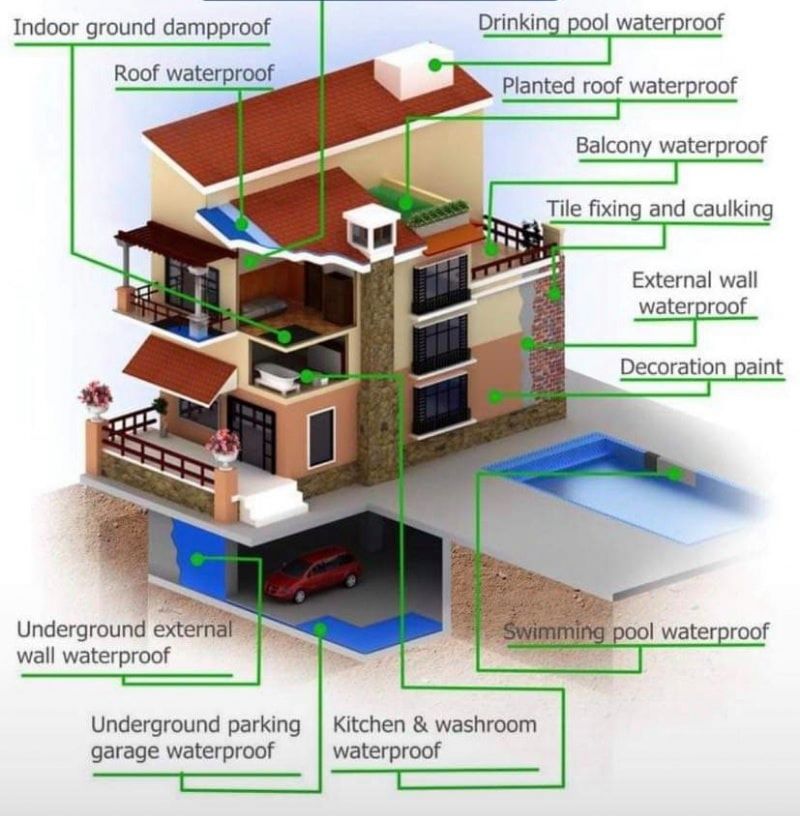

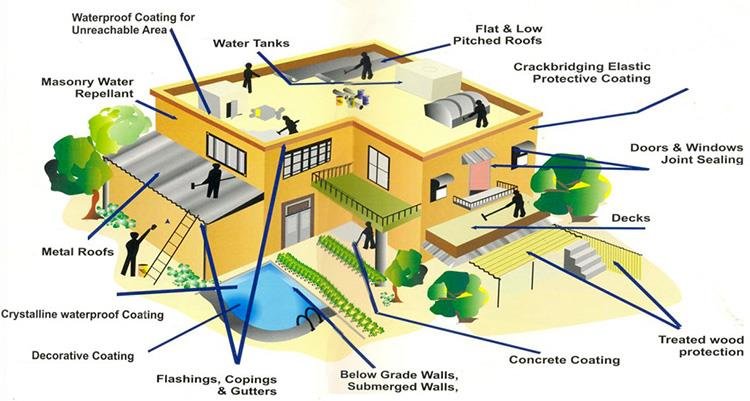

Ensuring waterproofing in buildings is crucial. From rooftops to basements, interior areas must remain dry to avoid issues like insect infestation, mold growth, and even structural failures due to water infiltration. Maintaining dry conditions inside buildings is paramount, as it not only reduces humidity but also shields interior contents from potential water damage. Additionally, waterproofing contributes to the structural integrity of buildings.

In regions with high annual rainfall and occasional flooding, waterproofing becomes indispensable. Foundations and basements, especially in areas with high groundwater levels, require effective waterproofing measures.

The use of waterproofing admixtures can render plaster and other construction materials water-resistant. Various methods, employing different chemicals and techniques, are available for waterproofing purposes.

Various Waterproofing Methods are Commonly Employed in Construction Projects

- Conventional waterproofing, such as Brick Bat Coba.

- Cementitious waterproofing.

- Chemical waterproofing.

- Liquid waterproofing membrane.

- Bituminous coating waterproofing.

- Bituminous membrane waterproofing.

- Polyurethane liquid membrane waterproofing.

- PVC membrane waterproofing.

- Crystalline waterproofing or Bio Concrete waterproofing.

Importance Of Water Proofing

Waterproofing systems can be tailored for indoor or outdoor installation, depending on water damage severity or owner preference.

The essence of waterproofing in construction lies in safeguarding buildings from the detrimental effects of water and humidity. These effects can manifest in various forms, including health hazards, structural decay, corrosion (akin to cancer in buildings), facility damage, and other complications.

1. Property Damage Risk: Even a minor leak can wreak havoc on interiors, damaging vital structural components such as floor joints, beams, studs, and frames. It can also lead to paint blistering and plasterboard swelling, posing risks of short circuits in lighting and power outlets. Such damages not only mar the building’s appearance and structure but also provide conducive environments for mildew and mold growth.

2. Health Risks: Moisture intrusion fosters the growth of fungi, molds, and mildew inside buildings, posing significant health risks. Airborne spores can trigger allergic reactions, asthma attacks, and various infections and irritations. Additionally, stagnant water may attract mosquitoes, exacerbating health concerns, such as dengue fever. Timely roof waterproofing helps mitigate these health hazards, ensuring a safe indoor environment for occupants.

3. Longevity: Waterproofing establishes a protective membrane on the roof, shielding it from rain, snow, wind, decay, and wear. This membrane also reflects sunlight, reducing the adverse effects of extreme light and heat on the roof’s integrity and enhancing comfort indoors. Prioritizing waterproofing can preempt future complications and maintenance headaches. Moreover, it prolongs the roof’s lifespan, averting costly damages. Most waterproofing solutions offer durability of up to ten years, extending the roof’s longevity and preserving its structural integrity.

4. Cost Saving: Waterproof roof coatings offer simplicity in repair and maintenance, offering substantial savings compared to overhauling or repairing an entire roof. Beyond reducing wear and tear, waterproof coatings are more cost-effective than extensive repairs. They minimize the need for frequent maintenance and repairs, thus alleviating financial burdens. As prevention is superior to cure, investing in waterproofing mitigates the risk of exorbitant repair costs in the future. Consequently, installing waterproofing systems translates into significant long-term cost savings, making it a prudent investment.

Our Solutions

Waterproofing from Barklay Polymers offers a range of products designed to protect roofs from water leakage and weather damage. The company provides comprehensive solutions for safeguarding roofs against water leakage in various locations and applications, backed by technical support.

Barklay Polymers offers unique products for complete building enveloping, assisting clients in achieving optimal cooling and waterproofing treatments for their projects.

Barklay Polymers provides two types of waterproofing:

A) Protective Grade Waterproofing

B) Exposed Grade Waterproofing

A) Protective Grade Waterproofing: This is involves waterproofing surfaces and protecting them with screed/tiling, typically applied to the base slab in new construction projects. This includes:

1. FAP (Fabric Applied Protective Waterproofing)

2. 2K Waterproofing (2-component waterproofing)

In FAP waterproofing, fabric reinforcement is combined with Barklay Polymers’ 2K waterproofing chemicals, such as Hi Seal slurry liquid and Hi Seal slurry powder or cement. This creates an on-site emulsion that binds strongly to the substrate, accommodating expansion-contraction and bridging cracks.

B) Exposed Grade Waterproofing: This is suitable for existing roofs or those directly exposed to sunlight. This type of waterproofing also offers cooling benefits, including:

FASC (Fabric Applied Sustainable Cooling)

Benefits of Barklay Polymers Systems include:

– Formation of highly tough and flexible cooling and waterproof layers.

– Applicability on China Mosaic defective roofs.

– Extended lifespan of 4 to 5 years compared to conventional products.

– Ideal for existing roofs.